MIL-STD 810 H

Price 10000.0 INR/ Kilograms

MIL-STD 810 H Specification

- Purity

- High Suitable for industrial testing

- Shelf Life

- Stable under dry, sealed storage conditions

- Grade

- Laboratory

- Type

- Industrial Lab Chemicals

- Appearance

- Powder

- Purity(%)

- 99%

MIL-STD 810 H Trade Information

- Minimum Order Quantity

- 10 Kilograms

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About MIL-STD 810 H

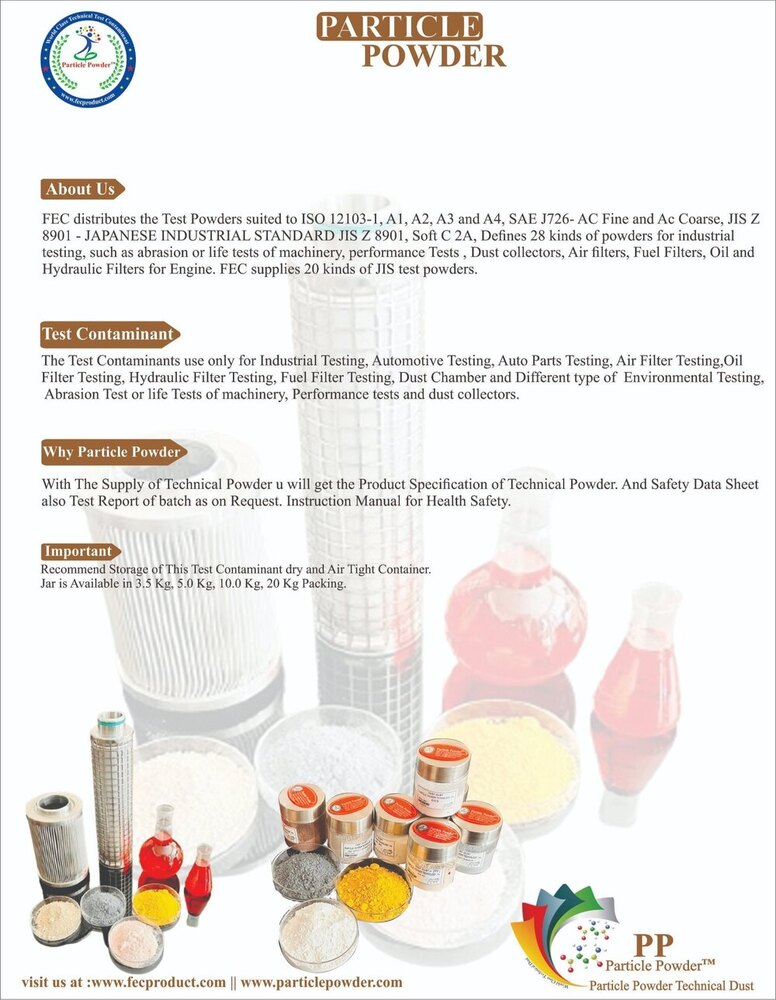

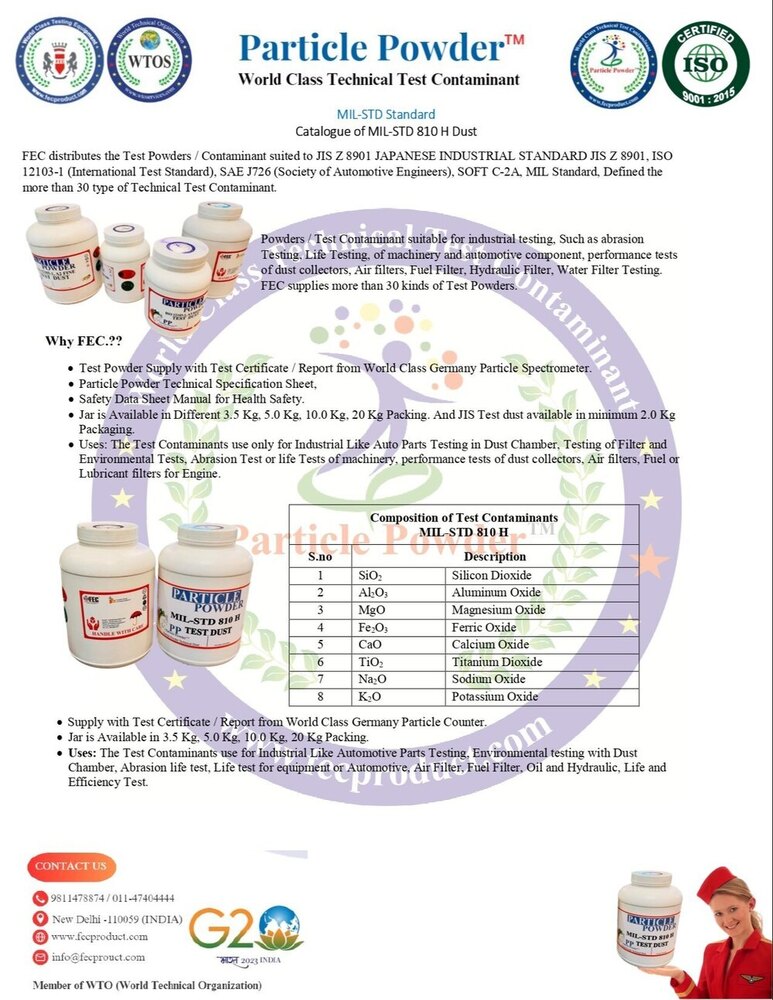

Identity: Arizona sand including Arizona Test Dust, Arizona Road Dust, Arizona Silica, AC Fine and AC Coarse Test Dusts, SAE Fine and Coarse Test Dusts, J726 Test Dusts, ISO 12103-1 A1 Ultrafine Test Dust, ISO 12103-1, A2 Fine Test Dust, ISO 12103-1, A3 Medium Test Dusts and ISO 12103-1, A4 Coarse Test Dust, MIL STD 810F Blowing Dust.Identity: Arizona sand including Arizona Test Dust, Arizona Road Dust, Arizona Silica, AC Fine and AC Coarse Test Dusts, SAE Fine and Coarse Test Dusts, J726 Test Dusts, ISO 12103-1 A1 Ultrafine Test Dust, ISO 12103-1, A2 Fine Test Dust, ISO 12103-1, A3 Medium Test Dusts and ISO 12103-1, A4 Coarse Test Dust, MIL STD 810F Blowing Dust, Portland dust, MIL-STD 810HFEC proudly stands at the forefront of technical contaminant innovation, offering a curated selection of world-class test powders engineered to meet and exceed ISO 12103-1 (A1 to A4), SAE J726 (AC Fine & Coarse), JIS Z 8901, Soft C 2A, and various MIL, IS, and global testing standards. Our collection includes 28 precision-formulated industrial powders, with 20 specialized JIS-grade variants, trusted by top-tier industries worldwide.

Crafted for cutting-edge performance validation, FEC test powders are essential for abrasion testing, endurance trials, and environmental simulations. Whether its automotive filters, hydraulic systems, air purification units, or dust chamber protocols, our contaminants deliver unwavering consistency, calibrated particle precision, and reproducible test resultsevery time.

With a legacy of technical excellence and global compliance, FEC empowers R&D labs, OEMs, and quality assurance teams with the confidence to test, validate, and innovate without compromise.

High Purity and Consistent Quality

With a purity level of 99%, MIL-STD 810 H powder is crafted to deliver reliable performance in critical laboratory and industrial settings. Its stable nature makes it ideal for repeated testing and research applications, meeting strict industry and laboratory requirements in India and globally.

Ideal for Industrial and Laboratory Testing

The product is suitable for extensive industrial testing as well as advanced laboratory experiments. Its precise formulation ensures compatibility with a variety of testing protocols, enhancing result accuracy and reliability across multiple sectors.

Reliable Shelf Life and Safe Handling

Maintained under dry, sealed conditions, MIL-STD 810 H boasts a long shelf life without compromising its effectiveness. Proper storage ensures ongoing quality, safeguarding your investment for extended use while minimizing material degradation.

FAQ's of MIL-STD 810 H:

Q: How should MIL-STD 810 H powder be stored for optimal shelf life?

A: MIL-STD 810 H powder should be stored in a dry, sealed environment to preserve its high purity and stability. Proper storage under these conditions ensures a long shelf life and prevents contamination or degradation.Q: What are the primary industrial applications of MIL-STD 810 H?

A: This chemical powder is primarily used for laboratory testing, material analysis, and environmental simulations in compliance with standardized protocols. Its high purity makes it suitable for advanced R&D, quality control, and reliability assessments in various industries.Q: When is MIL-STD 810 H most beneficial to use in laboratory processes?

A: MIL-STD 810 H is most beneficial during procedures that demand high-purity reagents, such as precision testing, calibration, or environmental simulations where consistent results and minimal impurities are crucial.Q: Where is MIL-STD 810 H manufactured and supplied from?

A: MIL-STD 810 H is manufactured, exported, and supplied by leading chemical producers in India, making it widely available to laboratories and industries around the world.Q: What is the process for using MIL-STD 810 H in industrial testing?

A: Typically, the powder is integrated into laboratory protocols according to specific testing requirements. It can be measured, mixed, or combined with other reagents to facilitate simulations or assessments, always following the safety and handling guidelines provided.Q: How does the high purity of MIL-STD 810 H benefit industrial users?

A: The 99% purity ensures that results obtained from testing are accurate and repeatable, with minimal interference from contaminants. This enhances confidence in experimental outcomes and supports compliance with stringent industry standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Technical Contaminant Particle Powder Category

JIS Z 8901 Class 1 Quartz Sand

Price 10000.0 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Purity(%) : 99%

Appearance : Powder

Purity : 99%

Grade : Laboratory

JIS Z 8901 Class 2 Quartz Sand

Price 10000.0 INR / Unit

Minimum Order Quantity : 10 Units

Purity(%) : 99%

Appearance : Powder

Purity : 99%

Grade : Laboratory

SAE J726 AC Coarse

Price 10000.0 INR / 10 Kilograms

Minimum Order Quantity : 10 Kilograms

Purity(%) : 99%

Appearance : Powder

Purity : 99%

Grade : Laboratory

SAE J726 AC Fine

Price 10000.0 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Purity(%) : 99%

Appearance : Powder

Purity : High Suitable for industrial testing

Grade : Laboratory

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry